developed length formula for sheet metal Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending .

$66.00

0 · sheet metal flat length formula

1 · sheet metal flat length

2 · sheet metal development length formula

3 · sheet metal design length formula

4 · sheet metal blank length calculator

5 · metal sheet development formula

6 · metal sheet development calculation

7 · how to calculate sheet metal

Whether you're a beginner or an experienced CNC enthusiast, this guide offers valuable insights to turn your passion into a profitable venture. Explore creative ideas for CNC projects to sell, including customized cutting boards, .

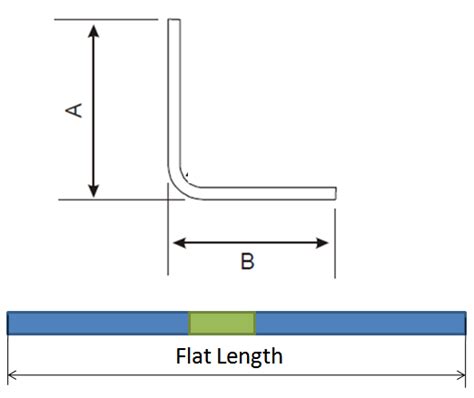

If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend .Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = . The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter .

When a developed length is calculated in radians, the equation is extremely simplified because the radian is the actual arc length, so no additional “translation” into angles .Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending .We also know the developed length of the sample (P). By doing P – (X+Y), we can get the bend allowance (BA) for the sample. Now, use Eqn.1 and you will get K factor. This K factor will be same for the actual product. Use this K factor .

The formula for bending sheet metal involves using the K factor, bend radius, and bend angle to calculate the flat pattern length. It’s typically calculated as: Flat Length = [(π × .To give users an understanding of sheet metal calculations in general and how they are used in SolidWorks, this article will review the following: The definition of both bend allowance and . We are going to give two very simple formulas to calculate the neutral fiber in an “L” shape and another one for a “U” shape and we will see it with an example for each case. Formula: Development = Flat face A + Flat face B + ¶ / 2 x (inner radius + neutral fiber) Let’s put an example with real measurements to do the calculation;

sheet metal flat length formula

If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × .Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correct length of the flat. The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.

To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter + . When a developed length is calculated in radians, the equation is extremely simplified because the radian is the actual arc length, so no additional “translation” into angles is needed as in the “standard” formula below.

outdoor electrical enclosure

Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending radius, and material characteristics.We also know the developed length of the sample (P). By doing P – (X+Y), we can get the bend allowance (BA) for the sample. Now, use Eqn.1 and you will get K factor. This K factor will be same for the actual product. Use this K factor value to . The formula for bending sheet metal involves using the K factor, bend radius, and bend angle to calculate the flat pattern length. It’s typically calculated as: Flat Length = [(π × Bend Radius × Bend Angle) / 180] + [(2 × Material Thickness) + Bend Allowance].To give users an understanding of sheet metal calculations in general and how they are used in SolidWorks, this article will review the following: The definition of both bend allowance and bend deduction methods and how each of them relates to the actual sheet metal geometry.

We are going to give two very simple formulas to calculate the neutral fiber in an “L” shape and another one for a “U” shape and we will see it with an example for each case. Formula: Development = Flat face A + Flat face B + ¶ / 2 x (inner radius + neutral fiber) Let’s put an example with real measurements to do the calculation;If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × .Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correct length of the flat.

The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.

To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter + . When a developed length is calculated in radians, the equation is extremely simplified because the radian is the actual arc length, so no additional “translation” into angles is needed as in the “standard” formula below.Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending radius, and material characteristics.We also know the developed length of the sample (P). By doing P – (X+Y), we can get the bend allowance (BA) for the sample. Now, use Eqn.1 and you will get K factor. This K factor will be same for the actual product. Use this K factor value to .

The formula for bending sheet metal involves using the K factor, bend radius, and bend angle to calculate the flat pattern length. It’s typically calculated as: Flat Length = [(π × Bend Radius × Bend Angle) / 180] + [(2 × Material Thickness) + Bend Allowance].

sheet metal flat length

outdoor electrical box installation

outdoor electrical box metal

Both metal and wood box springs can provide excellent support for your mattress. The choice between the two depends on your specific needs and personal preference. Metal box springs are typically less expensive and .

developed length formula for sheet metal|metal sheet development formula